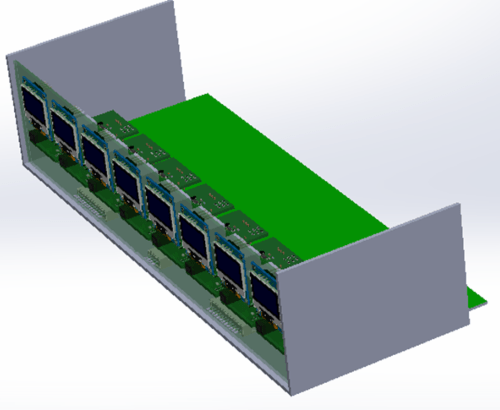

Case Study: 8 Channel High Precision Current Sensing Device

This case study explores the development of a cutting-edge 8-Channel High Precision Current Measurement Instrument starting from scratch, designed to meet the exacting demands of modern energy efficient devices.

Key Highlights

8 Channel Current Sense

Measurement Range: 200 nA to 1A

High Accuracy: 0.1% Of Reading

High Sampling Rate: 200 KSPS

7 Inch TFT Display with Touch

Remote Monitoring with Ethernet

High speed USB connectivity for PC

8 Input & 8 Output Configurable Trigger

| Engibrains’ Contribution

Segments We Worked On

Hardware

- Analog & Digital Mixed Signal

- 6 Layer Modular design

- 675+ Electronic Components

- Schematic & Layout design

- BOM Optimization

- Proto development & Bring-up

- Testjig development

- EMI/EMC Pre-compliance

- Enclosure Design & Integration

Firmware

- Application firmware

- Manufacturing Utility

- PC based GUI Application for Measure and control

- Bring up Utility

- Calibration Utilities

Pre-compliance & QA

- 200+ Test Cases identified

- Automated scripts for key scenarios

- Special firmware development for Pre-compliance testing

- Functional & Regression testing for periodic release

- Bug filing and report generation

Production

- Prototype batch#1,#2,#3

- Field trial batch#1

- Pre-compliant batch#1

| Technologies Used

Our Tech Stack will reduce your risk

HW Tools

- Schematic Design (Altium)

- PCB Layout design (Altium)

Language & Tool

- C

- RTOS

- Python

- QT

- Touch GFX

- MODBUS

- Eclips

- Pycharm

- Git

- Atlassian Jira

IF/Connectivity

- USB

- UART

- Ethernet

- I2C

- SPI

- 7 Inch TFT Display

QA Tools

- Digital Oscilloscope

- High-end DMM

- Hot Air Rework Station

- Thermal Camera

- Digital Microscope