Product Architecture

Circuit Simulation | Performance POC

I/O Specification | UI Mock-Up

MCU Selection | Class A Components

SW Module Interfacing

Hardware Design

Schematic Design | PCB Layout

Hi-speed Design | Low Power Design

BOM Identification | BOM Optimization

Prototype & Non-Form-Factor Design

Production Ready Design

Software Development

Linux | RTOS | Baremetal

SOC Software | MCU Firmware

BSP | SDK | Application

Connected Mobile Application

Connected Cloud Solution

Product Testing

Automated Test Suite | Simulator

Conformance Testing | CE/FCC/UL

WhiteBox Testing | BlackBox Testing

Static & Dynamic Code Analyser

Code coverage | Unit Testing

Managed Mass Production

PCB Fabrication & Assembly Through CM

Sourcing & Procurement Service

Automated & Manual QC

Testjig Automation

Packaging & Shipping

Product Maintenance

Alternate Component Identification

BOM Optimisation | NextGen Product Dev.

R&M Of Product | Fixing Of Field Issues

Feature Enhancement | Release Mgmt.

Embedded Product Engineering

An Extended Team To Build Your Customized Embedded Product

| One Stop Solution !

We Execute Turn-Key Projects For Customized Embedded Products

| Domains we are transforming !

Happy to build your innovative product leveraging our domain expertise

| Industry We Serve !

Our industry-ready engineers excited to solve a real-time problems

| Key Competency Map

Our Competency will reduce your risk

High Speed Design || Analog Design || Mixed Signal Design || Prototype Manufacturing || Enclosure Integration || Pre-Compliance || Certification || Mass Production || Product R&M

Bare Metal || RTOS || Embedded Linux || BSP Development || SDK Development || Application Development || Platform Porting || Product SW Support

Test Plan || Test Scenarios || Test-Bench || Test-Jig || Test Execution || Automation Framework || Automated Testsuite || Simulator Development || Instrument Automation

iOS App || Android App || Hybrid App|| Frontend Engineering || Backend Engineering || Cloud Micro Services || Cloud Analytics || Amazon AWS || Microsoft Azure || Google Cloud

| Testimonials

See what customers say about our engineering services

| Case Studies

Engineering marvels we delivered to market

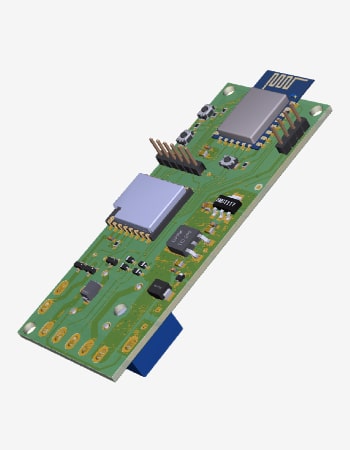

LoRa Enabled DMX Controller

Cloud Based BMS Monitoring for the Commercial Vehicle

Micro-object Detection Using 18 Mega Pixel Camera Sensor

Wireless Charging Battery Pack For Wearable Wrist Band

ANC+CVC Enabled Bluetooth 5.1 Neckband

Multichannel High Precision Low Current Sense Meter

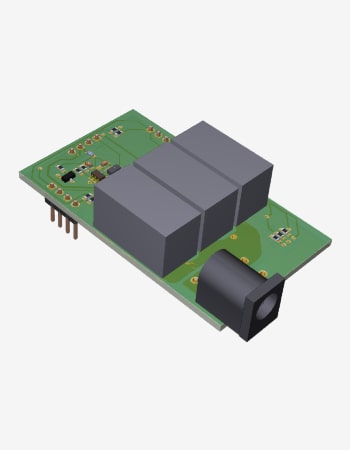

Industrial IOT - Modular Digital Pressure Measurement Device

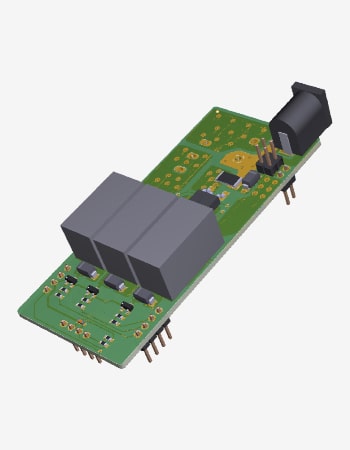

Custom Low Current & Voltage Measurement Platform

Multichannel High Precision Low Current Source Generator