Prototype Production

Low Volume Production

We provide cost-effective low volume manufacturing & prototyping services to our customers which requires trial batch quantities ranging from a hundred to thousands. We handhold our customer starting from initial product design & prototype development to quality inspection to production.

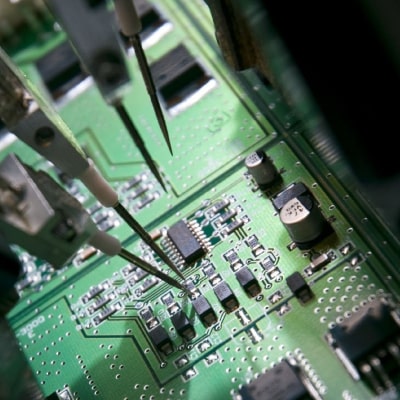

Manual QC Check

Even after numerous quality inspections, there is always a possibility that one or more product functions will have problems. Our Manual QC Check takes case of improper reflow configurations, dry soldering, component mounted with incorrect orientation, components missed out to populate, component damage due to excess heating, component shelf life is over and component batch has manufactured issues.

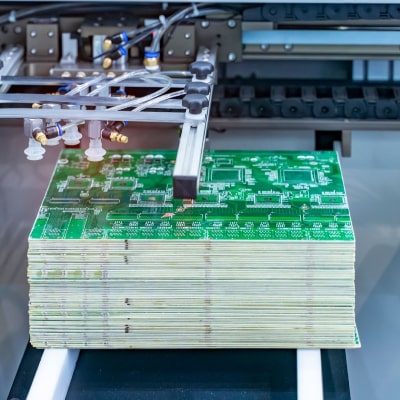

Mass Production

High Volume Production

- We understand the complexities and challenges involved in scaling up production while maintaining quality and efficiency. Our team of skilled professionals has extensive knowledge of production processes, supply chain management, and quality assurance, enabling us to deliver exceptional results.

- Our deep understanding of embedded production eco-system helps to scale up customers' operations, meet market demands, and achieve our customer's business objectives.

Testjig Automation

- Automation is needed to assist functional testing and signal testing incorporated into a manufacturing assembly line in order to increase test efficiency and production yield.

- We help our customers to design and develop a test Bed Of Nails (BON) which is a specially designed PCB having lots of pogo pins placed in such a way that it can touch the test points of the PCB. The test bed of nail (BON) is placed in a special mechanical assembly having a plunger mechanism to make sure that there is no loose contact once HW PCB under test is placed in mark up area. This fixture will include buttons, LED, LCD, and other indicators built in that aid start the test and shows the test’s outcome.

Cost Optimization & Obsolation management

BOM Optimization

All the products designed need to go through the BOM optimization from time to time, to be competitive. The BOM optimization needs to go through vendor negotiation, design optimization, and identification of alternate components based on the need of the product. Some of the products face component obsolete issues and in such cases, we help customers to redesign HW with minimal changes so that the customers can sell the product at the same price without compromising the functionality of the product. There also are cases where we help customers to merge multiple variants of HW products into a single PCB design and maintain versions by DNP of some of the components, which will save the significant cost of inventory.

Vendor Re-negotiation & New Vendor Identification

Engibrains Technologies streamline customers production support processes by offering comprehensive Vendor Re-negotiation & New Vendor Identification services. We leverage years of experience in the industry, to identify vendors who specialize in delivering components and services tailored to customers specific needs. We carefully evaluate each vendor, considering factors such as reliability, quality standards, cost-effectiveness, and ability to meet production timelines. Our team works closely with customers organization to review existing vendor contracts and identify areas for improvement. We analyze pricing structures, terms and conditions, delivery schedules, and performance metrics to ensure you are getting the best value for your investment.

Alternate Component Procurement

Sometimes there will be a very high lead time and production needs to be completed before that to meet market demand. In this condition, we help customers to identify the alternate components with no design change/minimum design change to support the production timeline.

Prototype Production

Low Volume Production

We provide cost-effective low volume manufacturing & prototyping services to our customers which requires trial batch quantities ranging from a hundred to thousands. We handhold our customer starting from initial product design & prototype development to quality inspection to production.

Manual QC Check

Even after numerous quality inspections, there is always a possibility that one or more product functions will have problems. Our Manual QC Check takes case of improper reflow configurations, dry soldering, component mounted with incorrect orientation, components missed out to populate, component damage due to excess heating, component shelf life is over and component batch has manufactured issues.

Mass Production

High Volume Production

- We understand the complexities and challenges involved in scaling up production while maintaining quality and efficiency. Our team of skilled professionals has extensive knowledge of production processes, supply chain management, and quality assurance, enabling us to deliver exceptional results.

- Our deep understanding of embedded production eco-system helps to scale up customers' operations, meet market demands, and achieve our customer's business objectives.

Testjig Automation

- Automation is needed to assist functional testing and signal testing incorporated into a manufacturing assembly line in order to increase test efficiency and production yield.

- We help our customers to design and develop a test Bed Of Nails (BON) which is a specially designed PCB having lots of pogo pins placed in such a way that it can touch the test points of the PCB. The test bed of nail (BON) is placed in a special mechanical assembly having a plunger mechanism to make sure that there is no loose contact once HW PCB under test is placed in mark up area. This fixture will include buttons, LED, LCD, and other indicators built in that aid start the test and shows the test’s outcome.

Cost Optimization & Obsolation management

BOM Optimization

All the products designed need to go through the BOM optimization from time to time, to be competitive. The BOM optimization needs to go through vendor negotiation, design optimization, and identification of alternate components based on the need of the product. Some of the products face component obsolete issues and in such cases, we help customers to redesign HW with minimal changes so that the customers can sell the product at the same price without compromising the functionality of the product. There also are cases where we help customers to merge multiple variants of HW products into a single PCB design and maintain versions by DNP of some of the components, which will save the significant cost of inventory.

Vendor Re-negotiation & New Vendor Identification

Engibrains Technologies streamline customers production support processes by offering comprehensive Vendor Re-negotiation & New Vendor Identification services. We leverage years of experience in the industry, to identify vendors who specialize in delivering components and services tailored to customers specific needs. We carefully evaluate each vendor, considering factors such as reliability, quality standards, cost-effectiveness, and ability to meet production timelines. Our team works closely with customers organization to review existing vendor contracts and identify areas for improvement. We analyze pricing structures, terms and conditions, delivery schedules, and performance metrics to ensure you are getting the best value for your investment.

Alternate Component Procurement

Sometimes there will be a very high lead time and production needs to be completed before that to meet market demand. In this condition, we help customers to identify the alternate components with no design change/minimum design change to support the production timeline.

| Our Mass Manufactured Projects

Engineering marvels we delivered to market

Micro-object Detection System using Lens-Free Image Sensor

Industrial IOT – Digital Pressure Measurement Device

Workspace Utilization & Air Quality Monitoring System

Low Current & Voltage Measurement Platform

| Lab Capability

Our QA engineers are well equipped with analysis & monitoring tools.

DMM6500 6½-Digit Digital Multimeterr

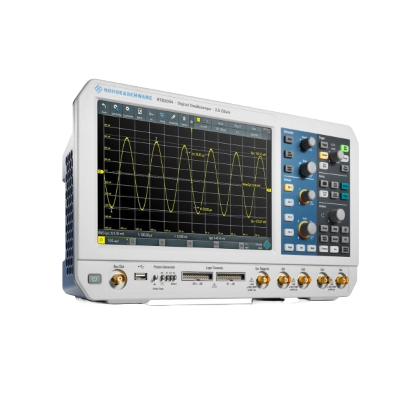

R&S®RTB2000 oscilloscopes

RSA306B USB spectrum signal analyzer

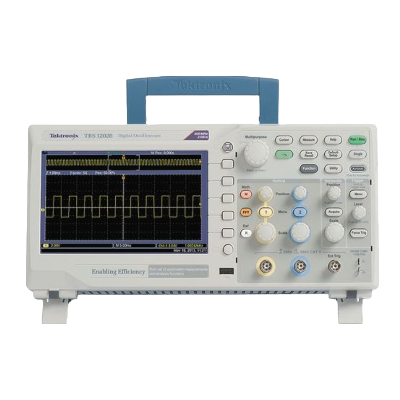

TBS1102B Digital Storage Oscilloscope

Aoyue 866 All in 1 Digital Hot Air Rework Station

Fluke High-end Digital Multimeter

FLIR C5 Compact Thermal Camera

Tabletop 1080P Digital Microscope